Discover SENGA pneumatic cylinders

What is a pneumatic cylinder (or pneumatic actuator) and how does it work?

Pneumatic cylinders (also called pneumatic actuators) are products used to provide linear or rotary motion and force to automated systems such as machines and processes in industrial applications.

Some examples of applications:

- Clamping or moving a load along a linear path.

- A gripper with suction cups used to handle glass.

Typically located at the end of a compressed air system, pneumatic cylinders and actuators operate when compressed air under pressure (between 1 and 10 bar) is introduced into a chamber of the cylinder to move the piston inside the cylinder. The cylinder rod, which is integral with the piston, is used to transmit force and movement. The mechanical energy is thus converted into a practical use, such as an automated picking and positioning system in production lines.

Cylinders (or pneumatic actuators) are a simple and effective way to obtain force and generate precise linear and/or rotary motion. They convert pneumatic energy into mechanical energy. They are able to withstand and operate in hostile environments, even at extreme temperatures.

Lightweight and low-maintenance, they generally produce less force and lower speed than hydraulic or electric cylinders, but are still a cost-effective and efficient alternative.

SENGA offers a wide range of "standard" (standard strokes) or "special" (custom stroke, magnetic...) pneumatic cylinders, according to our customers' needs and the international or national standards in force such as ISO (6432, 15552 etc...) or AFNOR NF E49.001 (ex CNOMO), CETOP.

How do the different pneumatic cylinders work and what are their components?

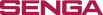

The following components are usually found inside pneumatic cylinders:

(1) : the nose/bottom "heads" (high strength anodised aluminium alloy or stainless steel)

(2): the piston (technopolymer, NBR, steel or aluminium alloy)

(3): the piston rod (ground chrome steel or stainless steel)

(4) : the tube or bore/cylinder/barrel (anodised aluminium or stainless steel)

(5): the wiper seal (NBR, polyurethane, FKM-Viton)

(6): guide neck - guide bearings (self-lubricating sintered bronze)

(7) : seals (NBR, polyurethane, FKM-Viton)

(8) : decelerators (aluminium alloy)

(9): tie rods/screws (steel or stainless steel)

(10): stem nut (steel or stainless steel)

The wiper seal serves to protect the cylinder from external contamination, sealing and holding on the rod.

The guiding of the piston rod is ensured by the guiding neck (bearings), usually made of self-lubricating sintered bronze (to minimise the friction coefficient).

Sealing between the two chambers of the cylinder or between the body and the rod is ensured by seals which can be made of NBR, PU or FKM-Viton, depending on the operating conditions

In general, there are two main categories of pneumatic cylinders:

1) The single-acting pneumatic cylinder: It has an "inlet", where compressed air enters and pushes the piston in one direction. The piston is then returned to its original position by means of a compression spring. Single-acting pneumatic cylinders have a limited stroke, so they are useful for low-speed applications. However, they consume a smaller volume of air, thus reducing operating costs.

2) The double-acting pneumatic cylinder: it has two ports that allow pressure to be applied in one of the two fields to move the piston and therefore the rod in a given direction. One chamber fills with air under pressure (inlet), the other chamber empties (outlet).

There is also the pneumatic rotary actuator, designed to transform the linear path of the piston into a rotary path by coupling the rack and pinion.

Finally, we can mention the rodless pneumatic cylinder, whose main advantage is its small size. Long strokes are available. These cylinders are used in robotic systems, and are very interesting for handling light parts over long distances. They also reduce the risk of buckling of the rods of conventional cylinders on long strokes.

Several options can be added to the standard cylinders, including: magnetic sensor version, through rod version, tandem, mechanical rod locks, single and double guiding unit, adjustable limit switch (screw)/adjustable decelerators, anti-rotation device, stainless steel rod, axial feed.

Technical specifications

A pneumatic cylinder is determined by its stroke, the diameter of its piston and its working pressure:

- The stroke corresponds to the length of the movement to be made.

- The force generated depends on the fluid pressure and the piston diameter.

In general, the larger the cylinder bore, the higher the force output.

We can determine :

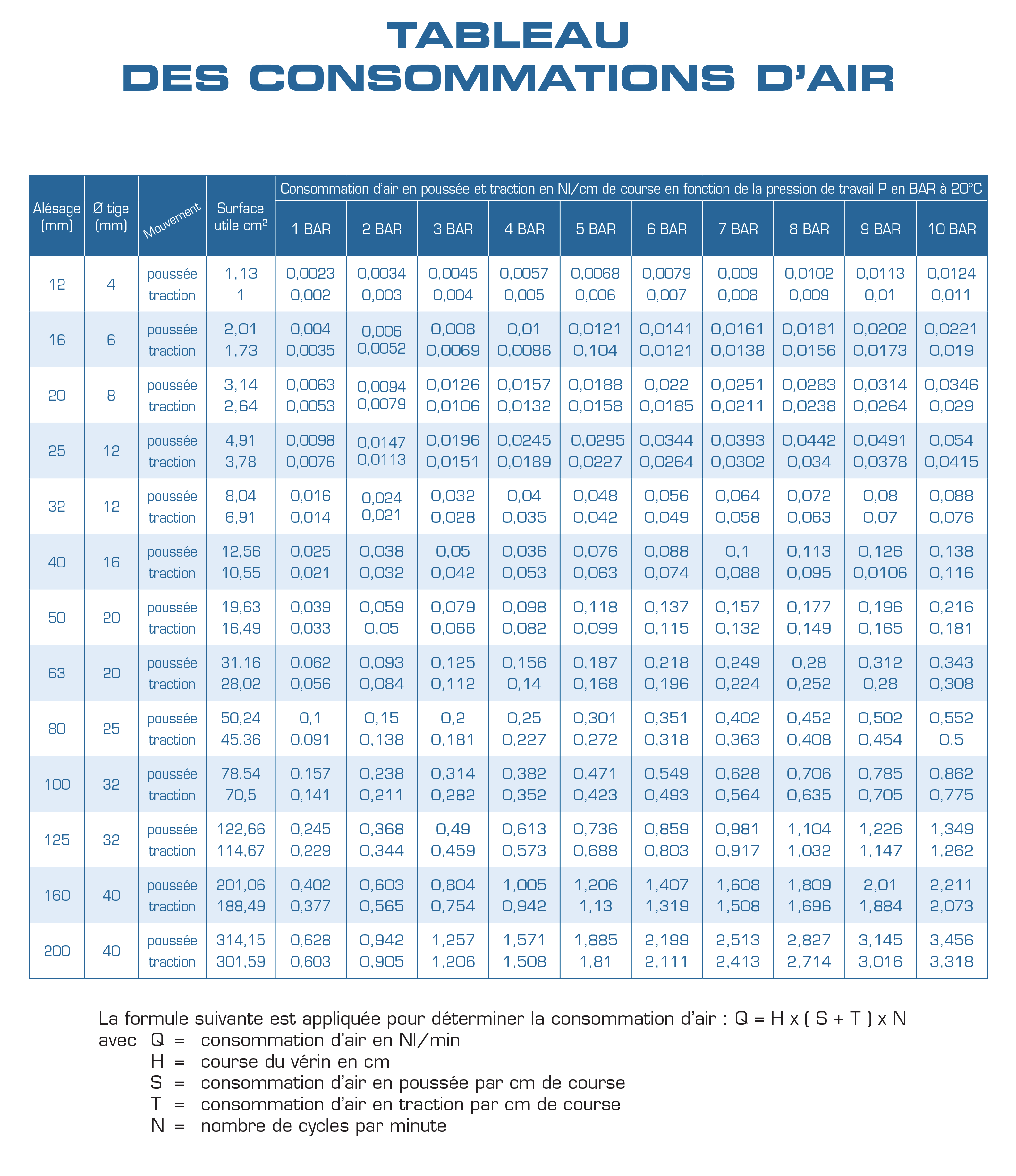

The force (in daNewton daN) is given by the following formula: F = P x S where P is the pressure in bar and S is the effective piston area (in cm2).

The speed (in m/s) of the piston's output is given by the following formula: V = Q / S where Q is the volume flow rate (in m3/s) and S is the effective piston area (in m2).

How to choose a pneumatic cylinder or actuator?

The type and characteristics of the actuator you need are dictated by the application. Several parameters have to be taken into consideration: fluid, working temperature and pressure, minimum/maximum stroke, cushioned stroke length, stroke tolerance, force to be developed (choice of bore diameter) etc.

The cylinders or actuators are available in a range of diameters from Ø8 mm to Ø320 mm, and perform different functions according to the customer's specifications.

The 5 main key factors for choosing a pneumatic cylinder or actuator are:

- Type of motion: the pneumatic cylinder required depends on whether the motion is rotary or linear.

- Pressure and flow requirements: consider what you expect from the pneumatic actuator or cylinder, depending on your application. This also applies to the other components required; if they are incorrectly sized, energy efficiency will be low, as will the efficiency of the installation.

- Operating conditions: Thanks to the development of technology and especially corrosion resistance, pneumatic cylinders and actuators can be used in extreme temperature ranges. Stainless steel cylinders with FKM-Viton seals are available in our range.

- Single or Double Acting: Pneumatic actuators generally fall into one of two categories depending on the type of application, the force or movement required, the nature of the work and the precision or control required.

- Application: Several types of pneumatic actuators or cylinders are available, including rodless, tandem, through rod, round profile, square grooved, compact, short stroke etc.

Discover our range of pneumatic cylinders:

Various types of pneumatic cylinders and actuators are available in our range:

CX series pneumatic cylinders AFNOR NF E49.001 (ex CNOMO)

The CX series cylinders are of the "external tie rod" and "protruding" type, with mounting dimensions according to AFNOR NF E49-001 (ex CNOMO).

The basic unit is separate from the accessories, except for the one with "trunnion" fixing.

The CX series is divided into 9 bores (Ø 32, 40, 50, 63, 80, 100, 125, 160, 200).

The cylinders can also be supplied in the magnetic, "through rod" version.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C) and 0° C ÷ +150° C with FKM - Viton seals

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 5 mm

- Maximum stroke: 3000 mm in double acting

- Stroke tolerance: ± 1,5 mm

Possible options: stainless steel, magnetic, through rod.

On request: Single acting, tandem and FKM (Viton) seals

Pneumatic cylinders with profiled tube "square grooved" series X standard ISO 15552

The X-series cylinders have a "square grooved" profile tube, with mounting dimensions according to ISO 15552, making it completely interchangeable with the old ISO 6431/VDMA 24562 cylinders.

The basic unit is separate from the accessories, except for the one with "central trunnion" mounting.

The X series is divided into 6 bores (Ø 32, 40, 50, 63, 80, 100).

The X series cylinders can also be supplied in the "through rod" version.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C) and 0° C ÷ +150° C with FKM - Viton seals, in non-magnetic version only.

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 5 mm

- Maximum stroke: 3000 mm in double acting

- Stroke tolerance: ± 1,5 mm

Possible options: stainless steel, magnetic, through rod.

On request: single acting, tandem, FKM (Viton) seals.

XT-XL series pneumatic cylinders with profiled tube and embedded tie rods to ISO 15552

The XT (ex CPUI) series of cylinders have a profiled tube and embedded tie rods, with mounting dimensions according to DIN ISO 15552 (ex ISO 6431) and VDMA 24562.

They are the most widely used in industrial automation and have a long service life and are capable of operating even at high temperatures.

The XL series cylinders are extruded tube and external tie rods, with mounting dimensions according to DIN ISO 15552.

The base unit is separate from the accessories, except for the one with "central trunnion" mounting.

The XT series is divided into 6 bores (Ø 32, 40, 50, 63, 80, 100).

The XL series is divided into 5 bores (Ø 125, 160, 200, 250, 320).

XT-XL cylinders can be supplied also in the versions "through rod", magnetic, stainless steel rod, single acting or tandem.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C) and 0° C ÷ +150° C with FKM-Viton seals, in non-magnetic version only.

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 5 mm

- Maximum stroke: 3000 mm in double acting

- Stroke tolerance: ± 1,5 mm

Possible options: stainless steel, magnetic, through rod.

On request: single acting, tandem, through rod, FKM (Viton) seals.

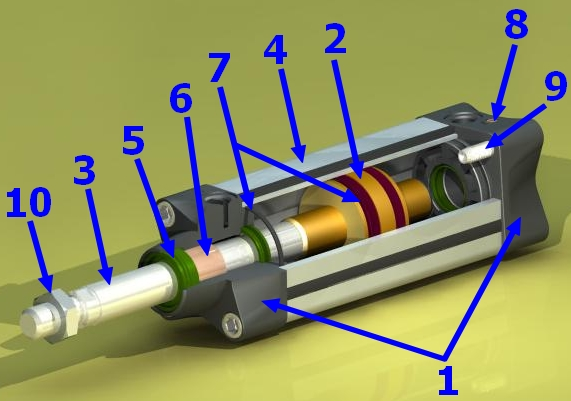

AX series stainless steel pneumatic cylinders to ISO 15552

The stainless steel cylinders of the AX series have an extruded tube and external tie rods, with mounting dimensions according to ISO 15552.

They are offered as standard in the magnetic version and are equipped with adjustable decelerators, making them particularly suitable for use in aggressive environments.

The basic unit is separate from the accessories, except for the one with "central trunnion" mounting.

The AX series is divided into 9 bores (Ø 32, 40, 50, 63, 80, 100, 125, 160, 200).

The cylinders can also be supplied in the "through rod" version.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C)

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 5 mm

- Maximum stroke: 1000 mm in double acting

- Stroke tolerance: ± 1,5 mm

Possible options: through rod.

On request: FKM-Viton seals for use in aggressive environments only (high temperature excluded).

Pneumatic cylinders series U CETOP / ISO 6432 standard

The U series cylinders are produced with mounting dimensions according to CETOP RP52P / ISO 6432.

The U series is divided into 6 bores (in mm): 8 - 10 - 12 - 16 - 20 - 25

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C) and 0° C ÷ +150° C with FKM-Viton seals

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 2 mm

- Maximum single acting stroke (mm): Ø 8 - 10 - 12 = 20 and Ø 16 - 20 - 25 = 50

- Maximum double acting stroke (mm): Ø 8 - 10 = 150 and Ø 12 - 16 = 250 and Ø 20 - 25 = 1000

- Cushioned stroke length : Ø 16 L = 17 mm and Ø 20 L = 18 mm and Ø 25 L = 18,5 mm

- Possible options: single rod, through rod, magnetic, single and double acting.

On request:

- Mechanical rod lock (Ø 20 and 25).

- Anti-rotation hexagonal rod (Ø 20 and 25).

- Single and double guide unit (Ø 12 to 25).

- Stainless steel accessories.

- FKM (Viton) seals.

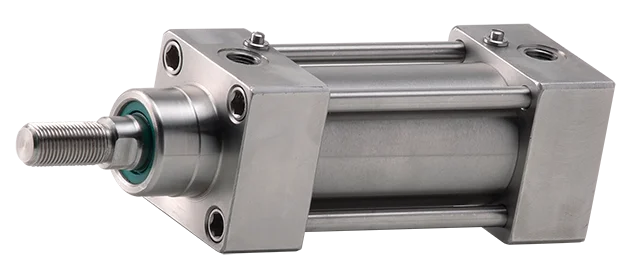

Pneumatic cylinders with aluminium & stainless steel round profile, series P

The cylinders of the P series are designed with a round profile from Ø 32 to Ø 63.

They are available in the basic version without adjustable cushions and are suitable for use with magnetic sensors.

The P series is divided into 4 bores (in mm): 32 - 40 - 50 - 63.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C) and 0° C ÷ +150° C with FKM-Viton seals

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 2 mm

- Maximum single acting stroke (mm): Ø 32 ÷ 63 = 50

- Maximum double acting stroke (mm): Ø 32 ÷ 63 = 1000

Possible options: single rod, magnetic, double and single acting, rear axial supply.

On request: FKM (Viton) seals.

Stainless steel pneumatic cylinders round profile ISO 6432 series AU

The AU series cylinders are made of stainless steel, with mounting dimensions according to ISO 6432, and in double acting version only.

The AU series is divided into 3 bores (in mm): 16 - 20 - 25

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -35° C) and 0° C ÷ +150° C with FKM-Viton seals, in non-magnetic version only (with dry air -10° C).

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 5 mm

- Maximum stroke: 1000 mm

Possible options: single rod, through rod, magnetic.

On request: with adjustable cushioning (Ø 20 and 25) and FKM-Viton seals

Stainless steel pneumatic cylinders round profile AP series

The AP series cylinders are made of stainless steel, with non-standard mounting dimensions (round profile).

mounting dimensions (round profile).

The AP series is divided into 4 bores (in mm): 32 - 40 - 50 - 63

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -30° C) and 0° C ÷ +150° C with FKM-Viton seals (with dry air -10° C)

- Working pressure: 1 ÷ 10 bar

- Minimum stroke: 5 mm

- Maximum stroke: 1000 mm

Possible options: single rod, through rod, magnetic, double acting.

On request: with adjustable cushioning (single rod version only) and FKM-Viton seals.

Integral pneumatic cylinders HB series

The HB series cylinders are of the integral type, i.e. with the mountings incorporated in the heads.

The HB series is divided into 9 bores for each single and double acting version.

This series is only available in a non-magnetic version.

The cylinders can also be supplied as "through rod" type (except series DFP).

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C) and 0° C ÷ +150° C with high temperature seals (with dry air -20° C)

- Working pressure: 1,5 ÷ 10 bar

- Service life: 5000 Km (in optimal use conditions)

- Bores: 20, 27, 35, 40, 50, 58, 70, 85, 100

- Connections : Ø 20 ÷ 50 = G1/8 Ø 58 ÷ 100 = G1/4

- Standard strokes (mm): 10, 15, 20, 30, 40, 50, 60, 70, 80, 90, 100, 150, 200, 250

- Max. strokes double acting (mm): Ø 20 - 58 = 2000 Ø 70 ÷ 100 = 1000

- Max. single acting strokes : Ø 20 27 35 40 50 58 70 85 100 mm 20 25 35 60 70 60 70 90 100

- Max. strokes single acting : Ø 20 27 35 40 50 58 70 85 100 with spacers mm 60 75 105 180 210 210 270 300

Possible options: single and double acting version.

On request: through rod.

Aluminium pneumatic cylinders ISO 21287 series BX

The BX series cylinders are aluminium profile tubes with mounting dimensions according to ISO 21287.

The BX series is divided into 8 bores (Ø 20, 25, 32, 40, 50, 63, 80, 100).

The cylinders can be supplied in female rod, male rod, through rod, single acting retracted rod, single acting extended rod, and with anti-rotation device.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C)

- Working pressure: 2 ÷ 10 bar for single acting 1 ÷ 10 bar for double acting

- Bores: 20, 25, 32, 40, 50, 63, 80 and 100

- Minimum stroke: 5 mm

- Maximum stroke: Ø 20 - 25: 150 mm in double acting

- Ø 32 to 63: 300 mm double acting

- Ø 80 - 100 : 400 mm double acting

- Ø 20 - 100 : 25 mm single acting

- Ø 20 - 25 : 40 mm anti-rotation

- Ø 32 to 100 : 80 mm anti-rotation

- Stroke tolerance: ± 1.5 mm

- To be used with magnetic sensors series FM100

Possible options: single (rod extended and retracted) and double acting, female and male rods, through rod and with anti-rotation device.

On request: anti-rotation version.

Compact" pneumatic cylinders AFNOR NF E49-004-1 and NF E49-004-2 (ex UNITOP RU-P/6 RU-P/7) series BU

The BU series cylinders comply with AFNOR NF E49-004-1 and NF E49-004-2 standards and are interchangeable without the need for specific assembly.

In addition, they can be supplied with heads conforming to the ISO 15552 (ex ISO 6431) standard, from Ø 32 to Ø 100.

In the magnetic piston versions, the magnetic sensors are inserted into the grooves of the extruded profile.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air -20° C) and 0° C ÷ +130° C with FKM-Viton seals (+100° C in single acting version)

- Working pressure: single acting 2 ÷ 10 bar double acting 1 ÷ 10 bar

- Maximum strokes: double acting Ø 20 - 25 = 200, Ø 32 ÷ 63 = 300 Ø 80 - 100 = 400, single acting Ø 20 ÷ 100 = 25, anti-rotation Ø 20 - 25 = 40, Ø 32 ÷ 100 = 80

- Possible options: single and double acting, anti-rotation device, magnetic, male and female threaded rods.

On request: FKM (Viton) seals.

Pneumatic short stroke cylinders series B

The B-series cylinders are short-stroke and are mainly used for clamping applications due to their compact design and easy mounting by means of mounting holes. They are available in several versions: double-acting, single-acting with front spring, magnetic or not (on request: single-acting with rear spring, through rod, anti-rotation device).

The B series is divided into 10 bores: Ø 12, 16, 20, 25, 32, 40, 50, 63, 80 and 100.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ +80° C (with dry air: -20° C) and 0° C ÷ +150° C with FKM-Viton seals (with dry air: -10° C)

- Pressure: 1 ÷ 10 bar

- Connection: Ø 12 ÷ 20 = M5, Ø 25 ÷ 63 = G1/8, Ø 80 - 100 = G1/4

- Possible options: magnetic, anti-rotation device, single (rod retracted) and double acting.

RX series pneumatic rotary actuators

The RX series of cylinders is a rotary type. This series is progressively replacing the WR model as the latter becomes available.

The dimensions remain virtually identical (see table Pg 64).

They are designed to transform the linear path of the piston into a rotary path by coupling the rack and pinion.

The standard versions are designed for the possible installation of magnetic sensors (FM 100 series).

The angle of rotation can be adjusted on all models (± 5°).

The RX series is divided into 7 bores: Ø 32, 40, 50, 63, 80, 100 and 125.

- Fluid: filtered compressed air, lubricated or not

- Working temperature: 0° C ÷ 80° C (with dry air -20° C)

- Working pressure: 1 ÷ 10 bar

- Connections: Ø 32 = G 1/8, Ø 40 - 50 = G 1/4, Ø 63 - 80 = G 3/8, Ø 100 - 125 = G 1/2

- Standard rotation angles: 90°, 180°, 270°, 360

- Rotation angle adjustment: ± 5°.

Possible options: male or female pinion.

Pneumatic rodless cylinders series Z

The Z-series rodless cylinders develop a direct force transmission between piston and carriage. They are designed for applications where long strokes are required. They have been designed with reduced overall dimensions compared to standard cylinders with external rod.

The guided version allows working with free loads while offering good resistance to transverse forces.

The Z-series cylinders have adjustable dampers and are always equipped with a magnetic piston. They can also be fitted with magnetic sensors.

The Z-series is divided into 6 bores: Ø 18, 25, 32, 40, 50 and 63.

- Fluid: filtered compressed air, lubricated or not.

- Working temperature: 0° C ÷ 80° C (with dry air -20° C)

- Working pressure: 2 ÷ 8 bar

- Maximum stroke: Ø 18 ÷ 63 = 6000 mm

Possible options: single guide.

On request: versions with short carriage and double guide.

Conclusion

In conclusion, pneumatic cylinders, also known as pneumatic actuators, play a critical role in providing linear or rotary motion and force to automated systems in industrial applications. These cylinders operate by introducing compressed air under pressure into a chamber, causing a piston to move and transmit force through a connected rod. With components such as piston heads, rods, tubes, seals, and bearings, pneumatic cylinders are capable of converting pneumatic energy into mechanical energy efficiently.

There are two main categories of pneumatic cylinders: single-acting and double-acting. Single-acting cylinders utilize compressed air to move the piston in one direction, while double-acting cylinders can move the piston in both directions by applying pressure to either chamber. Additionally, pneumatic rotary actuators are designed to convert linear motion into rotary motion, offering versatility in automation systems.

Several factors must be considered when choosing a pneumatic cylinder, including type of motion, pressure and flow requirements, operating conditions, and application-specific needs. Various types of pneumatic cylinders are available, including standard, stainless steel, rodless, and rotary actuators, each with its own set of features and specifications to meet diverse industrial requirements.

SENGA offers a wide range of pneumatic cylinders tailored to customers' needs and compliant with international standards such as ISO and AFNOR NF. From compact cylinders to rodless cylinders to rotary actuators, there are numerous options available to optimize automation systems for efficiency, reliability, and performance in industrial environments.