New range of pneumatic quick-connect safety couplings ISO-B

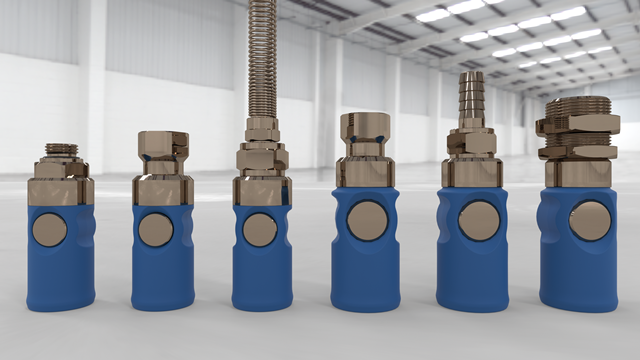

We offer a brand new range of ISO B profile safety couplings in our catalogue: anti-scratch design series (SP20) available in 5.5 and 8 mm passages (ISO 6150-B12 and ISO 6150-B15).

Secures the operator, respects sensitive surfaces: whip-check safety, anti-scratch design

In many industrial environments, pneumatic systems are ubiquitous for powering a multitude of equipment and machinery. However, the use of compressed air under pressure poses inherent risks, notably the risk of whip-check incidents during circuit disconnection. Whip-check incidents can occur when compressed air is rapidly released from pipelines, creating a sudden and violent force upon disconnection. These accidents can result in severe, even fatal, injuries to operators and damage to surrounding equipment. Faced with this issue, it is crucial to implement effective safety measures to prevent accidents and ensure a secure working environment for all. It is with this aim that the ISO-B SP20 safety couplers are designed, offering a reliable solution to minimize the risks of whip-check incidents and ensure a secure disconnection of pressurized pneumatic circuits.

The issue of scratches caused by pneumatic couplers on sensitive surfaces, such as car bodywork, is a major concern in many industrial and automotive environments. Scratches can not only compromise the aesthetic appearance of surfaces but also lead to permanent damage requiring costly repairs. In automotive body shops, for example, where finish quality is paramount, even minor scratches can have a significant impact on the final result of the work. Operators must therefore be particularly vigilant when using pneumatic couplers to avoid direct contact with delicate surfaces. However, despite precautions taken, scratches can sometimes be unavoidable, especially in high-throughput production environments where speed and efficiency are essential. That is why the integration of anti-scratch features in the design of pneumatic couplers, such as that offered by the SP20 safety pneumatic coupler with its reinforced resin body, represents a significant advancement in the industry and in automotive garages. By significantly reducing the risk of scratches, these innovations allow operators to work with confidence while preserving the integrity of sensitive surfaces and minimizing maintenance costs.

Equipped with whip-check safety (ISO 4414) and anti-scratch design, our new SP20 compressed air safety coupler (also known as a quick-release safety coupling) is remarkable for its lightweight (composed primarily of resin and aluminum) and compact size.

Its body made of glass fiber-reinforced resin (PA66 GF30%) and its swivel base made of aluminum (chemically nickel-plated) make it a robust solution against impacts, ergonomic, and high-performing (flow rate of 1650 Nl/min at 6 bar with an 8 mm passage). Our couplers are perfectly suited for environments where surfaces prone to scratches are found, such as car bodywork in automotive garages.

The two-stage disconnection (two pushes on the push button) ensures optimal safety for the operator. Indeed, the fitting can only be disconnected if the downstream air of the circuit has been completely purged beforehand.

A wide range to meet your needs

Advantages

- Scratch-resistant thanks to a carefully engineered design

- Impact resistance due to high-quality materials

- Whip-check safety: ISO 4414 Standard

- Double impulse (purge + disconnection)

- Hand-adjustable

- Lightweight

- Ergonomic design for a perfect grip

- Maneuverable

- Compact size

- Easy connection/disconnection under pressure: low coupling effort

- High flow rate for optimal tool performance

- Wide range available (DN5.5 and DN8 mm): male, female, barbed, spring fitting, bulkhead fitting...

- Customizable: we can laser engrave your logo and reference (or your client's) on the coupler

Technical Specifications

- Compatible Fluid: Compressed air

- Operating Pressure: from 0 to 16 bar and from 0 to 12 bar (depending on passage)

- Operating Temperature: between -20°C and +70°C

- Flow Rate: 1000 Nl/min and 1650 Nl/min (at 6 bar, Δp = 1 bar)

- Passages: 5.5 mm and 8 mm

- Passage Areas: 23.75 mm² and 50.26 mm²

- Profile Standards: ISO 6150 B-12 (US MIL 4109) and ISO 6150 B-15

- Whip-check Safety: ISO 4414 Standard

- Double-release disconnection

- Non-protruding push-button

- Coupling Effort: 76 N and 136 N (at 6 bar)

- Weight: 90 g - (for G1/4'' male); 135 g - (for G1/4'' male)

Versatile applications

Whether you work in the industry, automotive, construction, or any other field, our SP40 couplers are the ideal choice for your pneumatic connection needs. Their versatility makes them suitable for a variety of applications, ensuring optimal performance in all situations.

- Industry

- Garage

- Automobile

- Painting

- Aerospace

- Food industry

Components and Materials

The SP20 safety pneumatic coupler features meticulously crafted construction with a variety of materials selected for their robustness and durability. Its main body is composed of PA66 resin reinforced with 30% glass fibers, providing exceptional resistance to impacts and excellent longevity.

The swivel base is made of aluminum treated with a chemical nickel coating, ensuring high corrosion resistance and easy handling.

To ensure smooth and reliable operation, the push button, valve, sleeve, and cap are all made of steel treated with a chemical nickel coating. These materials also provide high wear resistance, ensuring prolonged use in demanding industrial environments.

Internal components such as clips, O-rings, springs, and balls are also carefully selected for their superior quality. Clips are made of AISI 302 stainless steel, ensuring secure and durable fastening, while NBR 70 Shore A O-rings provide optimal sealing even under high-pressure conditions.

Springs and balls are made of 420C stainless steel, ensuring increased corrosion resistance and reliability. By combining these high-quality materials, the SP20 coupler delivers exceptional performance and long service life, meeting the most rigorous requirements of industrial applications.

Conclusion

Don't leave operator safety or the integrity of scratch-sensitive surfaces to chance. Opt for peace of mind with the ISO-B series SP20 safety pneumatic couplers. Browse our online catalog today to discover our full range and choose quality and reliability for all your pneumatic connection needs.

Discover and purchase SP20 couplings

To discover our wide range of products, we invite you to consult our catalogue.