The new compressed air piping system in aluminium : SENfluid

In the industry, compressed air networks play a crucial role in powering a variety of equipment, but their installation and maintenance can often prove to be complex. One of the main challenges lies in the assembly of fittings and tubes, often requiring bulky and heavy tools, which prolongs lead times and complicates operations. Moreover, the considerable weight of the tubes and fittings can pose logistical and safety challenges on job sites. Concurrently, pressure losses in lower-quality tubes, such as galvanized steel, can lead to decreased performance and energy inefficiency of the system. In this article, we will closely examine these obstacles and explore innovative solutions to simplify installation and enhance the efficiency of compressed air networks.

SENfluid, patented connection technology at your service

SENfluid is a distribution system for compressed air designed in aluminium and reinforced resin.

This compressed air piping system is characterised by its lightness and its assembly/disassembly without tools (simple Allen key), which makes it an efficient and economical solution for routing fluids (compressed air and neutral gases) to points of use while minimising drop pressure.

The operating pressure can vary between 0 bar and 14 bar and the operating temperature between -20°C and +80°C.

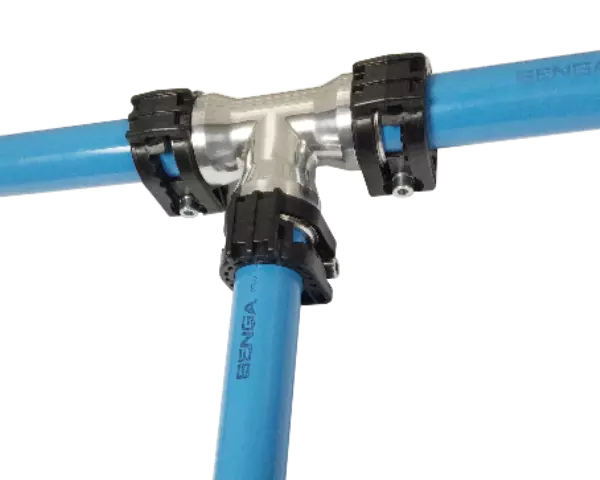

![]() Practical and simple: assembly and disassembly without the need for special tools and tightening of the tubes with an Allen key. Insertion of the tubes into the fittings without effort.

Practical and simple: assembly and disassembly without the need for special tools and tightening of the tubes with an Allen key. Insertion of the tubes into the fittings without effort.

![]() Light and resistant: network made of aluminium alloy, 30% glass fibre reinforced plastic resin and anti-corrosion treated steel.

Light and resistant: network made of aluminium alloy, 30% glass fibre reinforced plastic resin and anti-corrosion treated steel.

![]() Reliable and efficient: resistant to corrosion, temperature variations and mechanical shocks. Low pressure losses (very low roughness tube). Water separator at the level of the downpipes. Externally varnished aluminium tubes ensuring resistance to water and condensation: powder varnish certified non-toxic, UNI 9983 standard. Perfect seal at joints and excellent resistance to tearing. Tightening indication and protection of the tubes by a screw locking system. Complies with Directive 97/23/EC art.3.3 (PED: Pressure Equipment Directive).

Reliable and efficient: resistant to corrosion, temperature variations and mechanical shocks. Low pressure losses (very low roughness tube). Water separator at the level of the downpipes. Externally varnished aluminium tubes ensuring resistance to water and condensation: powder varnish certified non-toxic, UNI 9983 standard. Perfect seal at joints and excellent resistance to tearing. Tightening indication and protection of the tubes by a screw locking system. Complies with Directive 97/23/EC art.3.3 (PED: Pressure Equipment Directive).

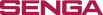

T fitting with water separating

![]() Modular and flexible: possibility to modulate and extend your installation according to your needs. Adaptable to the type of workshop: the connections can be adjusted.

Modular and flexible: possibility to modulate and extend your installation according to your needs. Adaptable to the type of workshop: the connections can be adjusted.

Technical specifications of the SENfluid compressed air network:

- Compatible fluids:

- Compressed air

- Neutral gases (argon, nitrogen)

- Operating pressure: from 0 bar to 14 bar (0 Psi to 203 Psi)

- Operating temperature: from -20°C to +80°C (-4°F to 176°F)

- Compatible tubes: Extruded and calibrated aluminum tubes (8300 series)

- Resistance to: Corrosion, mechanical shocks, thermal variations

- Sealing: Quadrilobal seals and NBR 70 Shore A O-rings

- Threads: Cylindrical BSP: G1/2”, G3/4”, G1”1/4

- Tube painting:

- Color: RAL 5012

- Electrostatic paint (certified non-toxic according to UNI 9983 standard)

- Tube properties:

- Diameters: ø20 - ø25 - ø40 mm

- Thickness: 1.5 mm Lengths: 3 or 6 meters

- Expansion coefficient: 0.024 mm/(m°C)

- Density: 2.70 kg/dm3

- Compliant with directive 97/23/CE art.3.3 (PED: Pressure Equipment Directive)

- Applications: Industry, Garage

Materials: optimized lightness and resistance

- Fitting bodies: EN AW 6061-T6 aluminum alloy

- Tubes: EN AW 6060-T6 extruded aluminum alloy

- Fixing flange: PA66 30% GF

- Quadrilobal and O-rings: NBR

- Clamping jaws and screws: treated steel

Assembly/disassembly: simplicity and safety

For assembly:

- Deburring: Deburr and clean the end of the tube with a cloth. Deburring of the tubes is imperative to avoid any damage to the sealing joints during tube assembly into the fittings. We recommend using a file from diameter 40 mm onwards.

- Greasing: Add oil or grease (check compatibility with NBR seals) to the end of the tube before insertion into the fitting.

- Insertion: Insert the tube into the fitting by rotating until it reaches the stop.

- Tightening: Tighten the screw until it locks to secure the tube: Do not force when the screw is locked. For diameter 20: stop tightening before full locking, do not force.

For disassembly:

- Loosening: Loosen the screw several turns.

- Unlocking: Give a sharp blow to the screw head then rotate the tube in both directions within the fitting to release the clamping jaws.

- Disassembly: Remove the tube from the fitting by pulling and twisting.

We invite you to read the article we have written on the 6 golden rules to follow to optimize your compressed air network: How to optimise your compressed air piping system?

Reminder: To optimize the efficiency of your compressed air network, several steps must be followed. Firstly, it is essential to build the main network in a "closed loop" to limit pressure losses. Then, it is crucial to carefully select the diameter of the tubes according to the intended use, which optimizes the airflow and avoids pressure problems. Moreover, connecting the compressor to the network using a flexible hose reduces vibrations and mechanical stresses. To anticipate thermal variations in the network, the use of flexible pipes allows for expansion or contraction absorption. Furthermore, it is recommended to slightly incline the main network to facilitate water flow to the purge point, ensuring better compressed air quality. Finally, to ensure a solid and secure fixation, it is recommended to place fixing clips approximately every 2 meters along the network. By following these recommendations, you can optimize the performance of your compressed air system and extend its lifespan.

Conclusion

In conclusion, SENfluid represents an innovative and effective solution to overcome the challenges related to the installation and maintenance of compressed air networks. With its lightweight design, tool-free assembly and disassembly, SENfluid simplifies on-site operations, thereby reducing associated delays and costs. Additionally, its resistance to corrosion, mechanical shocks, and thermal variations makes it a reliable and durable option for a wide range of industrial and garage applications. With a comprehensive range of fittings and advanced technical features, SENfluid offers exceptional flexibility and adaptability to meet the specific needs of each installation. By adopting SENfluid, you can not only improve the efficiency of your compressed air system but also ensure its long-term safety and performance.