Compressed air receiver tanks (sometimes also called "tanks") are essential mechanisms in a compressed air network. They are generally positioned at the compressor outlet to store large volumes of pressurised air. By acting as a real buffer between the compressor and the points of use, they make it possible to absorb peaks in compressed air consumption (fluctuating air flow) and to ensure continuous operation of the installation, even under fluctuating conditions of use.

The aim of using reservoirs is to avoid permanent load on the compressor (limited load/unload cycles of between 4 and 20 per hour) and thus to significantly reduce breakdowns, maintenance costs and air shortages. They form an air reserve between the compressor and the compressed air system. The pressure is thus kept constant and the air temperature is reduced.

How to size and choose a compressed air tank?

The sizing of a compressed air receiver is an important step. Indeed, if we take the example of piston compressors, these should not exceed 20% of the operating time. The tank must therefore be carefully chosen according to

- The compressor flow rate

- The regulation system

- The minimum and maximum pressure of your compressed air network

- The pressure drop in your system

- The maximum number of load/unload cycles allowed by your compressor, depending on its power. The more powerful your compressor is, the greater the number of cycles you can have (between 4 and 20 per hour maximum)

- The compressed air consumption of the installation, the following rule of thumb applies: for a required flow rate of 1 L/s you need a tank volume of between 10 and 15 L.

- If your compressed air consumption is constant, you will need a smaller tank than with peak consumption.

Our range includes tanks from 0.5 to 100 L. They can be vertical or horizontal, with or without feet.

The materials available are epoxy painted steel and polished AISI 304.

Installation of the tank

The installation must be carried out in such a way that :

- Easy access to the tank venting device, which is usually mounted underneath.

- Easy access to the safety valve control

- Protect the tank from impact

- Keep away from hazardous substances

- Tanks are subject to safety standards, we provide for each tank (batch number) a declaration of conformity with the relevant standards such as UNI EN ISO 14732:2013, UNI EN ISO 15613:2005 and EN ISO 15609-1:2006. Our tanks are 97/23/EC certified.

Operating instructions and condensation draining

The air tank is intended for storing compressed air for static use. Correct use is necessary to ensure the safety of the user:

- Use the air tank correctly within the pressure and temperature limits that are indicated on the manufacturer's plate and on the declaration of conformity.

- The air tank is not equipped with a safety system. You must ensure that the air tank is always equipped with safety and control accessories. These should be replaced, if necessary, by other accessories with the same characteristics. Please contact us.

- It is strictly forbidden to carry out welding operations on parts subject to air pressure.

- Do not use the air tank in environments where there is insufficient air exchange; do not install the air tank near heat sources or flammable substances.

- Equip the air tank with shock absorbers to avoid exposure to vibrations that could cause fatigue failure; do not fix it to the floor or to fixed parts.

- Monitor the tank for corrosion: depending on the conditions of use, condensation may accumulate inside the tank and should be drained daily. Check the condition of the tank every 6 months. Due to the compression phenomenon, the humidity present in the air is transformed into water droplets (condensation) and is propelled by the air into the tank. The condensation is further enhanced by the contact of the air with the metal wall of the tank, which is itself in direct contact with the outside environment, which is at a lower temperature. This phenomenon of air cooling will encourage condensation. We therefore recommend positioning the tank near the compressor in a cool place to facilitate the condensation of humidity.

- The connection between the compressor and the tank should be made by means of a flexible hose, which will be useful to attenuate the vibrations of the compressor.

Discover the SENGA range of compressed air tanks

Our range includes tanks made of epoxy painted steel or stainless steel. The volumes available in stock range from 0.5 L to 100 L, for any other volume, please consult us.

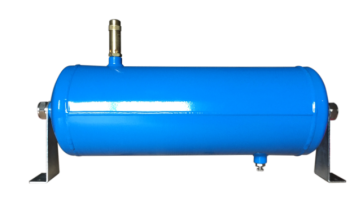

> Epoxy painted steel version SB-SBP

- Maximum working pressure: 11 bar

- Working temperature: -10°C to +60°C

- Construction: epoxy steel

- Fluid: filtered compressed air (with or without lubrication)

- Volumes: from 0.5 to 100 L

- With or without foot

- 97/23/CE certification

- G3/8" and G1/2" connections

> Standard stainless steel version SBX

- Maximum working pressure: 11 bar

- Working temperature: -40°C to +50°C

- Construction: polished AISI 304 stainless steel

- Fluid: filtered compressed air (with or without lubrication)

- Volumes: 5 and 12 L

- Without foot

- 97/23/CE certification

- Connections in G1/2''.

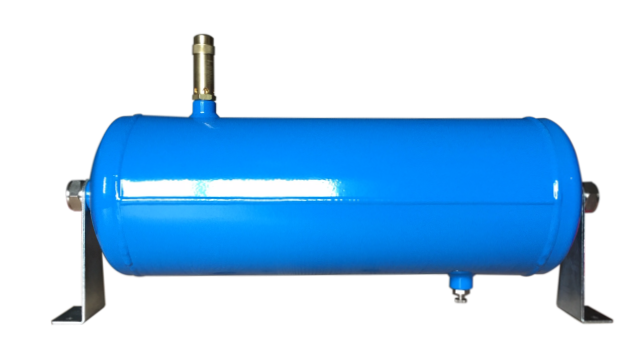

> Stainless steel version on legs SBPX

- Maximum working pressure: 11 bar

- Working temperature: -40°C to +50°C

- Construction: AISI 304 stainless steel (unpolished)

- Fluid: filtered compressed air (with or without lubrication)

- Volumes: 24 and 50 L

- With legs

- 97/23/CE certification

- Connections in G1/2''.

Conclusion

In conclusion, compressed air receiver tanks, often referred to as "tanks," play a vital role in compressed air systems by storing pressurized air and acting as a buffer between the compressor and points of use. They absorb peaks in compressed air consumption and ensure continuous operation, thus reducing strain on the compressor and minimizing breakdowns, maintenance costs, and air shortages. Proper sizing and selection of a compressed air tank are crucial factors, considering parameters such as compressor flow rate, pressure range, and the number of load/unload cycles allowed by the compressor. Our range of tanks, available in various sizes and configurations, meets industry standards and safety regulations, providing a reliable solution for compressed air storage needs. It's important to install and operate the tank according to manufacturer guidelines to ensure safety and optimal performance. Regular maintenance, including condensation draining and corrosion monitoring, is essential to prolong the tank's lifespan and maintain its efficiency. Explore our SENGA range of compressed air tanks, which includes epoxy painted steel and stainless steel versions, with volumes ranging from 0.5 L to 100 L, catering to diverse industrial applications and requirements.