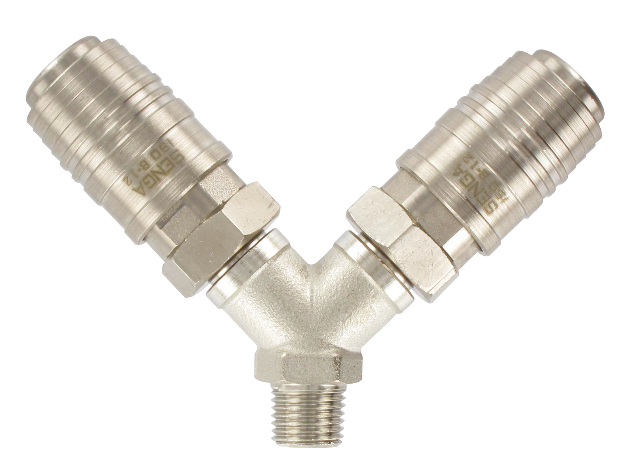

Pneumatic boosters

- The pneumatic booster is used to provide more pressure than is available at the inlet, at the expense of a loss of flow (as expressed in the equation of state for perfect gases pV=nRT).

➜ Operation

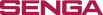

Mechanically, the multiplier consists of 2 interconnected pistons that alternately compress the air at the inlet; the pistons are controlled by a 5/2 valve, which is itself controlled by 2 pneumatic stroke fi ns.

The pressure intensifier is automatically activated as soon as the inlet pressure is applied and the outlet pressure has not yet reached twice the inlet pressure. The outlet pressure can be regulated by a pressure regulator mounted at the inlet. When no air is taken from the outlet, the multiplier will automatically stop as soon as the pressure has increased. The presence of integrated non-return valves allows

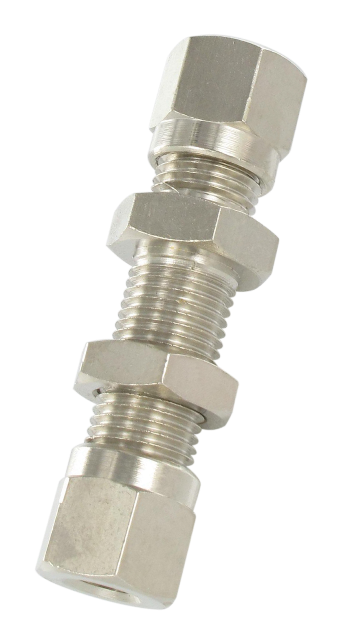

to maintain the increased pressure even when there is no pressure at the inlet.➜ Connection to a system

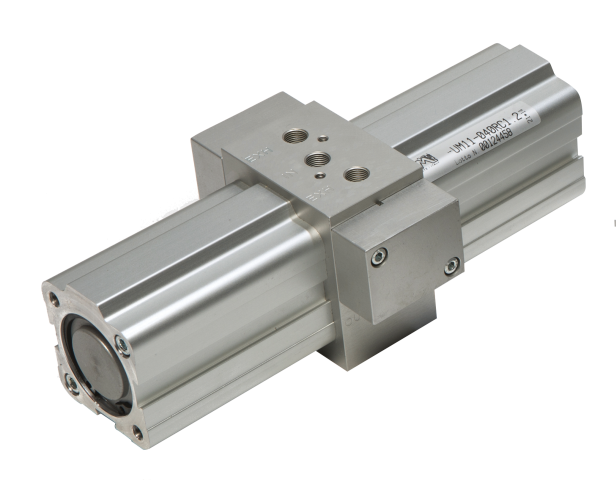

If the multiplier is connected directly to a system, a 3/2-way valve must be provided to open and close the circuit. It is advisable to always use an air tank (4) at the outlet of the multiplier to avoid pulsation during operation.

An optional non-return valve (5) can be useful to speed up the first filling of the system.

Pressure intensifiers are not designed to operate as a replacement for a compressor, but to provide momentary pressure increases on applications that require significant pneumatic force.➜ Maintenance

The pressure intensifier can have an average life of 20 million exchanges, under optimum operating conditions; a good degree of filtration (< 50 microns) helps to increase the life of the component. We recommend protecting the exhaust ports from dust with suitable filters.

Replacement kits for seals subject to wear can be supplied on request.➜ Technical data

Fluid: filtered compressed air (preferably without lubrication*)

Installation: it is preferable to install the assembly with the supply upwards.

*PLEASE NOTE: All sliding elements and seals are lubricated with a special high-performance grease. In case you start using lubricated air, you should persist constantly.

Supply pressure: 2,5 ÷ 10 bar

Working temperature: -20° C ÷ +50° C➜ Materials and components

- BODY AND HEAD: Aluminium 11s

- PISTON: Aluminium 11s

- ROD: chrome plated steel

- SEALS: NBR